Powering ASEAN’s Electric Future: MG’s 50,000-Unit Annual Capacity Facility

MG (SAIC Motor-CP) has opened its first electric vehicle (EV) battery production plant in Thailand, marking a significant step in the company’s expansion in Southeast Asia’s EV market.

Key Details

-

Location

The plant is situated in the NEW ENERGY INDUSTRIAL PARK within the WHA Eastern Seaboard Industrial Estate 2 (WHA ESIE 2) in Chonburi province.

-

Area

The facility spans approximately 75 rai (12 hectares).

-

Production Capacity

The plant can produce up to 50,000 battery units annually.

-

Investment

The initial investment for this phase of the NEW ENERGY INDUSTRIAL PARK is at least 500 million Thai baht (approximately $13.9 million USD).

Plant Features

-

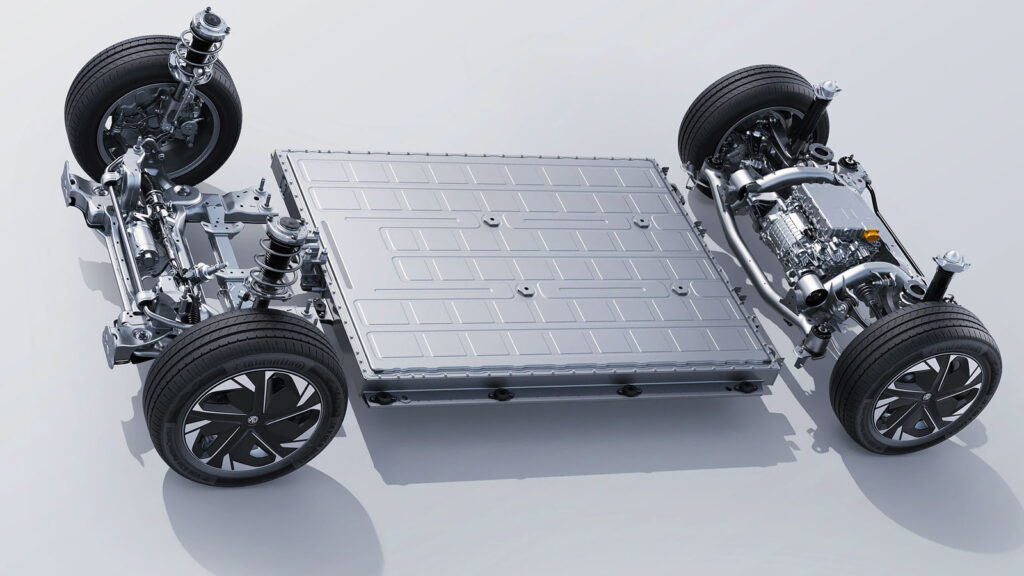

Battery Assembly Area

- Fully automated with cutting-edge robotic technology

- Uses Laser Welding for precision

- Employs Charge Coupled Device (CCD) for quality assurance

-

Battery Testing Area

- Involves over 60 testing processes

- Includes Charge & Discharge, Air Leak Test, Insulation Test, and Static Test

Technical Specifications

-

Technology

The plant will produce Cell-To-Pack (CTP) EV batteries using the new RUBIK’s CUBE BATTERY technology.

-

First Application

Batteries from this plant will be first installed in the MG4 ELECTRIC model, with plans to expand to other models in the future.

-

Strategic Importance

- This is the first EV battery factory of its kind in ASEAN.

- It strengthens Thailand’s position as an EV production hub for both domestic and ASEAN markets.

- The plant is part of MG’s broader strategy to develop a comprehensive EV ecosystem in Thailand.

-

Timeline

- The plant was in its production preparation phase as of October 2023.

- It is expected to be fully operational in 2024.

This development underscores MG’s commitment to the Thai and ASEAN EV markets, and aligns with Thailand’s goal of becoming a major EV production center in the region.